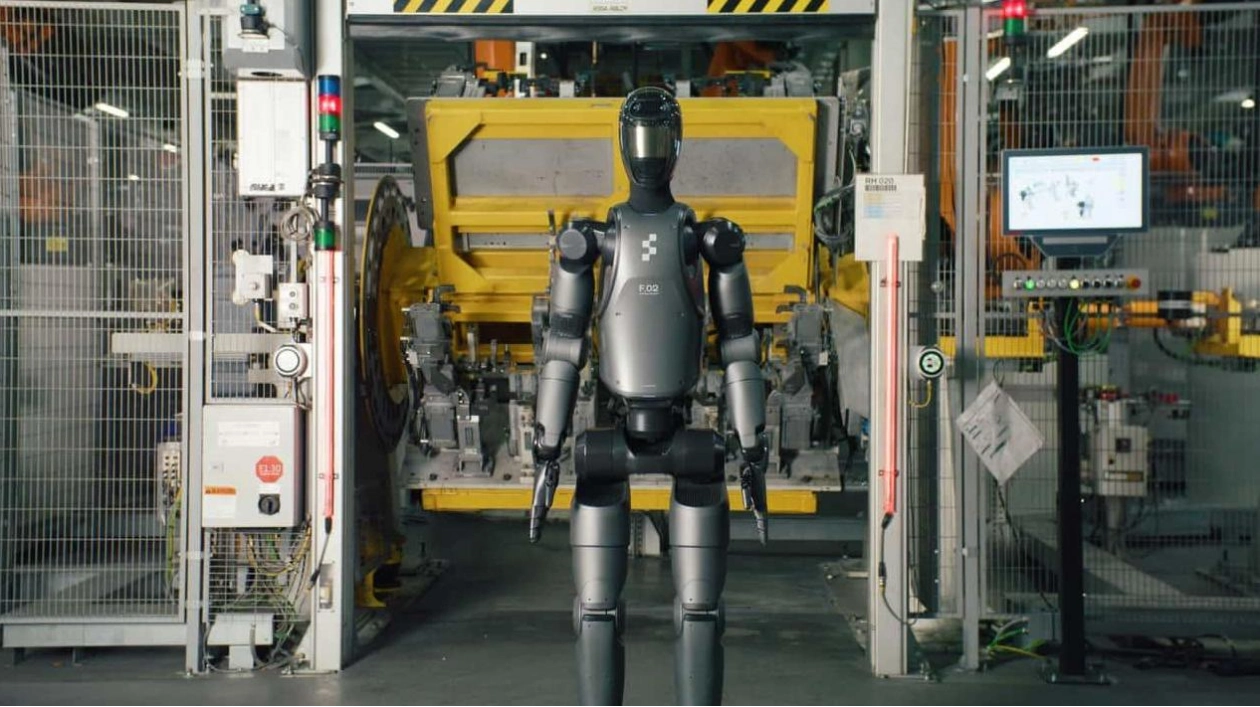

Meet Figure 02, a humanoid robot crafted by California's Figure company. Recently, BMW put it through its paces at the Spartanburg assembly plant, where it handled subassembly tasks on car components. The automaker is assessing the robot's potential in manufacturing. Figure claims it's the most advanced humanoid robot currently on the market, not a one-time creation like Boston Dynamics' backflipping prototypes. If BMW is impressed, these robots might someday assist humans in assembling your X5.

However, don't anticipate this soon. BMW reports the recent test of Figure 02 was successful, but it's still in the developmental and consideration stage. There are no Figure robots at the Spartanburg plant yet, and no timeline for their introduction. "The advancements in robotics are very encouraging," said Milan Nedeljkovic, a board member for production at BMW. "Through an early test operation, we are exploring potential applications for humanoid robots in production. We aim to guide this technology from development to industrialization."

During the evaluation, Figure 02 was assigned to insert specific sheet metal parts into fixtures. BMW monitored the robot's interaction with its environment, noting its dexterity designed to showcase precision and delicacy. Given BMW's positive feedback, it likely excelled. With the data collected, BMW is now partnering with Figure for further development and testing. Both envision Figure 02 filling roles that are "ergonomically awkward and tiring" for humans, potentially leading to widespread use as part of BMW's iFactory vision for future production.