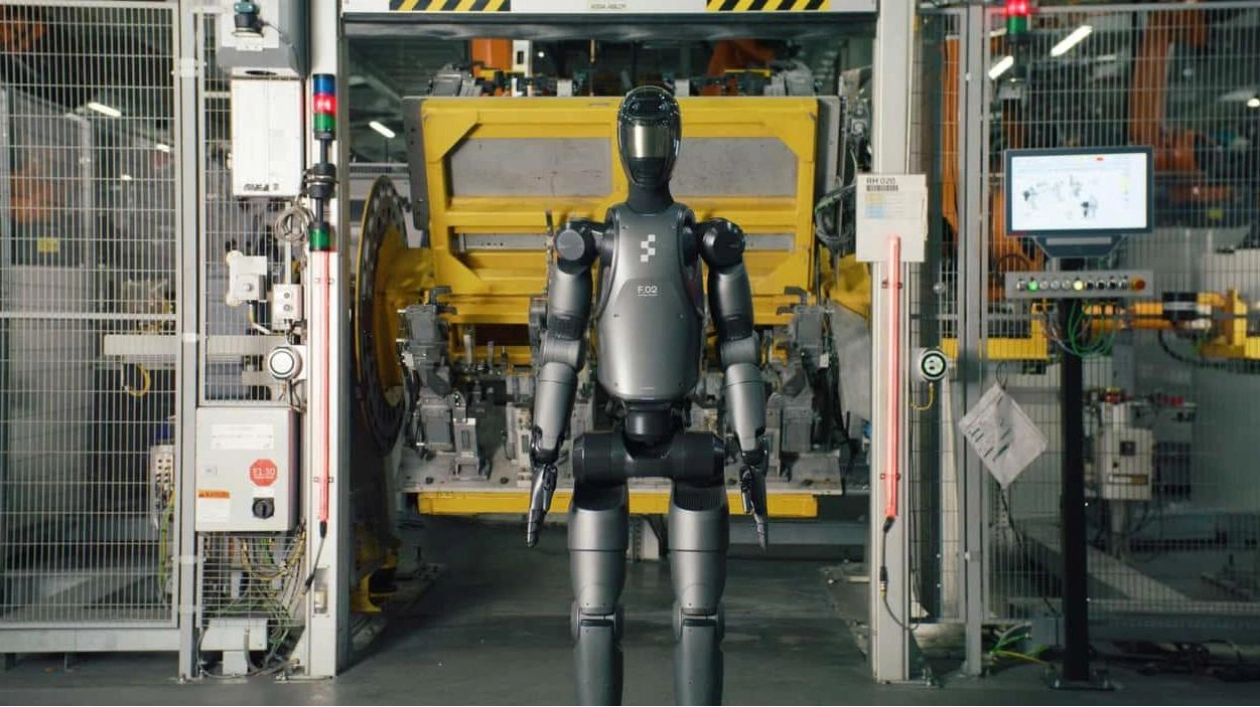

Meet Figure 02, a humanoid robot created by California-based company Figure. Recently, BMW tested this robot at their Spartanburg assembly plant, where it handled subassembly tasks on car components. The automaker is considering integrating this technology into their manufacturing processes. Figure claims that this robot is the most advanced humanoid model currently on the market for purchase and use, distinguishing it from one-off prototypes like those seen from Boston Dynamics. If BMW's evaluation is positive, there's a possibility of more of these robots assisting humans in assembling vehicles like the X5 in the future.

However, don't anticipate this happening soon. Although BMW reported a successful test with Figure 02, they are still in the early stages of development and consideration. BMW emphasizes that there are no Figure robots currently operating at the Spartanburg plant, and no specific timeline for their introduction. Milan Nedeljkovic, a member of BMW's board of management for production, expressed optimism about robotics advancements, stating, "With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialization."

During the evaluation, Figure 02 was assigned to insert specific sheet metal parts into fixtures. BMW not only monitored the robot's work but also observed its interaction with the environment. The tasks showcased the robot's precision and delicacy, earning high praise from BMW. Based on the data collected, BMW is now collaborating with Figure to advance the development and testing of Figure 02. Both companies envision the robot filling roles that are ergonomically challenging for humans, potentially leading to widespread adoption as part of BMW's iFactory vision for future production.