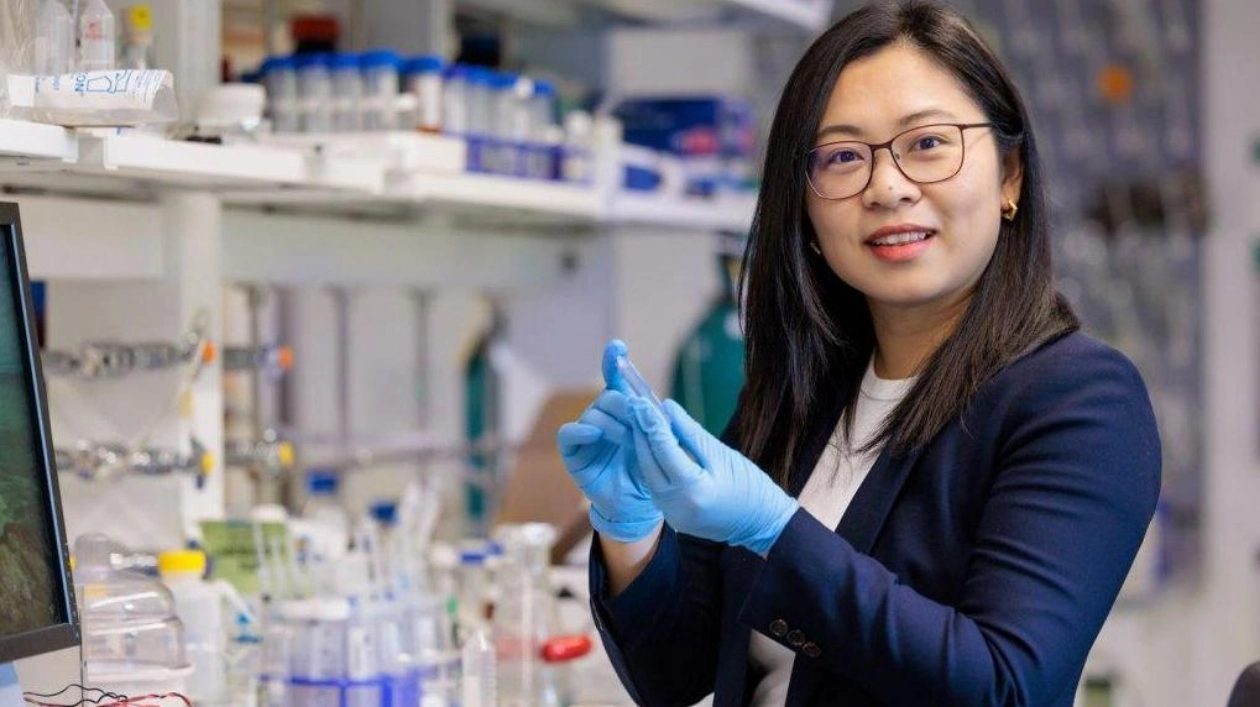

Electric vehicles hold the promise of reducing our reliance on fossil fuels, but they bring a new challenge: securing enough lithium for EV batteries (SN: 5/7/19). Materials scientist Chong Liu of the University of Chicago is working on solutions. Current technology can only extract lithium from sources with highly concentrated ions, such as hard rocks or underground brines. These sources are not only insufficient to meet future demand but also have environmental impacts (SN: 3/15/22). Liu has identified a material that could enable extraction from untapped sources. She is exploring brines from geothermal and desalination processes, wastewater from fracking, or even seawater, which could potentially provide a vast supply of lithium if harnessed. However, seawater has a sodium-to-lithium ratio of about 20,000-to-1, far higher than the current sources with ratios in the hundreds-to-one range. Extracting lithium ions from low-concentration solutions for commercial use will require significant research, Liu notes. But her work has made substantial progress toward more efficient resource extraction, says University of Chicago molecular engineer Matthew Tirrell, who recruited Liu as an assistant professor in 2018. Her research is also laying the groundwork for other processes involving ions in confined spaces, with potential applications ranging from accelerating chemical reactions to treating mercury or lead poisoning. The method Liu is developing, called electrochemical intercalation, involves immersing a material with ion-sized passageways into briny water. Lithium ions enter the material’s channels but are often crowded out by sodium ions. Liu began searching for the ideal material in 2016 during her postdoctoral work at Stanford University. She eventually settled on iron phosphate, which forms stronger bonds with lithium than with sodium. Once the material is saturated with ions, it is transferred to freshwater where electric currents are used to expel the ions, forming solid lithium hydroxide, a key component in EV batteries. Physicist Steven Chu of Stanford University, who worked with Liu during her postdoctoral research, describes the amount of lithium extracted by iron phosphate as “spectacular.” However, Liu is not content with just achieving impressive results; she is also focused on making the process practical. In her Chicago lab, Liu’s team is studying how lithium and sodium ions interact within the material’s channels to improve its efficiency. Additionally, they are developing a method for separating rare earth elements, which are crucial for modern technologies but difficult to isolate due to their similar properties. Beyond these specific projects, much of the lab’s work centers on fundamental materials science, accumulating knowledge to predict and innovate. This deep understanding sets Liu apart, says Chu, who considers her one of the few researchers consistently coming up with novel approaches. Liu’s passion for research was ignited during her Ph.D. at Stanford, where she discovered her love for solving scientific puzzles. On weekends, she balances her scientific pursuits with family time, playing Legos or riding bikes with her children, and subtly introducing them to scientific concepts.

Text: Lara Palmer

25.09.2024

Chong Liu's Research Aims to Secure Lithium from Untapped Sources for Future EV Batteries